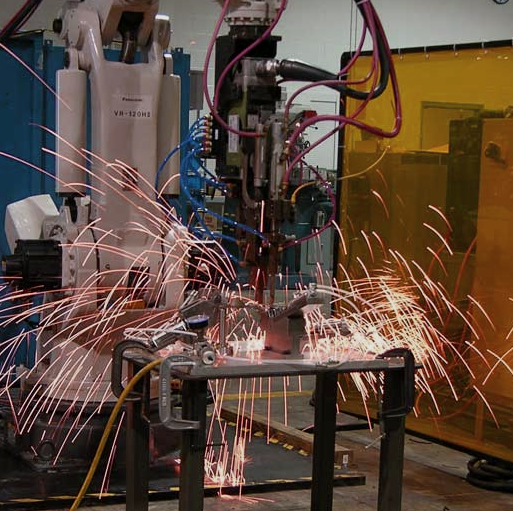

Spot welding is the most common welding application found in the manufacturing field. While it is commonly used in the automotive industry, the spot welding application has a variety of project uses.

Spot welding guns are normally designed to fit the assembly. Many basic types of guns are available, the two most commonly used being the direct acting type, generally known as a "C"-type gun, where the operating cylinder is connected directly to the moving electrode, and the "X"-type (also known as "Scissors" or "Pinch") where the operating cylinder is remote from the moving electrode, the force being applied to it by means of a lever arm. C guns are generally the cheapest and the most commonly used.

There are many variations available in each basic type with regard to the shape and style of the frame and arms, and also the duty for which the gun is designed with reference to welding pressure and current.

Pneumatic guns are usually preferred because they are faster, and they apply a uniform electrode force.

Hydraulic spot welding guns are normally used where space is limited or where high electrode forces are required. Spot welding robots should have six ore more axes of motion and be capable of approaching points in the work envelope from any angle. This permits the robot to be flexible in positioning a welding gun to weld an assembly.